This is a Portable Power Tool Safety training session to discuss safe use of portable power tools. As we will see, using portable power tools can be hazardous if you do not use them safely, but there are a number of safety guidelines you can follow to prevent injuries.

Table of Contents

Session Objectives

The objective of this session is to provide important information about power tool safety. Specifically, by the end of the session, you will be able to:

- Identify the hazards of portable power tools;

- Take precautions against injury;

- Use tool guards effectively and correctly; and

- Understand common safety practices for specific types of tools.

Types of Portable Power Tools

There are many types of portable power tools, using different sources of energy. Regardless of the type of tool, they all present dangers because of their power, speed, and sharp edges. Different types of power tools include:

- Electric;

- Pneumatic, or air-powered;

- Liquid fuel, such as gasoline;

- Hydraulic; and

- Powder-actuated

Portable Power Tool Hazards

There is a wide variety of power tool hazards, as well. It’s often easy to ignore these possible hazards, by thinking that you already know how to use the tool properly. But it’s important to recognize hazards such as the following:

- Being hit by flying debris;

- Being hit by a broken tool part;

- Puncturing yourself with a sharp tool;

- An explosion or fire when sparks from a tool ignite flammable or combustible materials;

- Electric shock from a frayed or defective power cord; or

- Musculoskeletal disorders, known as “MSDs,” from repetitive misuse of a tool, such as using an awkward grip or working in an awkward position.

General Precautions for Operating Power Tools

On this and the following slide, we’ll list several of the general precautions to keep in mind for operating power tools.

- Never carry a tool by the cord or hose, or yank the plug by the cord. This can damage the cord and lead to a fire.

- Disconnect tools when not in use to prevent accidental start-up.

- Make sure observers stay a safe distance away from you when you are using a power tool. Anyone who is too close may be hit by flying debris.

- Secure your work with a vise, clamp, or other support. Moving or unstable work surfaces can cause the tool to kick back and injure you.

- Keep cords and hoses away from heat, liquids, and sharp edges that might damage them and increase the risk of fire or shock.

- Examine tools before each use to make sure they are not damaged. A damaged power tool can create many hazards, from electric shock to the possibility of a flying part.

General Precautions (cont.)

More important general precautions are:

- Keep cutting tools sharp and lubricated to make sure they work properly.

- Do not wear loose clothes, ties, or jewelry when operating power tools. These can get caught in moving parts and lead to serious injury.

- Tie back long hair, for the same reason.

- Mark or tag all damaged tools with “Do Not Use.”

- Always wear personal protective equipment, or PPE, that is appropriate for the hazards of the work you are doing.

- Finally, use fire curtains for work you are doing around flammables. Make sure you have permits that might be needed, and take precautions before you start to work.

Tool Guards

Tool guards are important safety features of most power tools. Guards are there to protect you from:

- Point of operation hazards—that is, the point where the work is actually being performed, as where the blade of a saw meets the material;

- Nip points—where moving parts of a tool might catch a hand or finger;

- Rotating parts of all kinds, such as a saw blade; and

- Flying chips or sparks.

Guarded Power Tool Parts

The parts of a power tool that must always be guarded include:

- Gears, sprockets, and sprocket drive chains;

- Belt and pulley drives, pulleys, and drums;

- Hazardous revolving or reciprocating parts;

- Exposed shafts and projecting shaft ends; and

- Collars, clutches, and couplings.

Protect Yourself – Use Guards

Protect yourself from possible serious injury by always using guards on portable power tools. Follow these safety rules related to guards:

- Never operate a tool without its guard in place.

- Use the guard supplied by the tool manufacturer. If one is not available, get approval from your supervisor to adapt or construct another one that provides good protection.

- Never remove or disable a guard, or try to defeat its intended purpose in any way.

- Finally, report any missing, broken, or disabled guards to your supervisor.

Electric Tool Safety

Electric tool safety is a critically important consideration in using these tools properly. Misusing an electric-powered tool can result in electrical shock or electrocution, in addition to other power tool hazards. So keep these safety rules in mind for electric power tools:

- Operate electric tools within their design limitations – don’t try to make them do a job they are not intended to do.

- Wear appropriate gloves and footwear that are insulated to resist electric shock.

- Store tools in a dry location; moisture can cause a shock.

- Do not use them in wet or damp locations; again, moisture can affect the electric circuit on a tool, resulting in a shock as well as damage to the tool.

- Finally, work areas should always be well lighted. Hazards are increased when operators cannot see the work they are doing.

Power Grinder Safety

A power grinder is a good example of some of the safety considerations that are needed for portable power tools. Here are some safety rules for power grinders:

- Always use eye protection when using a power grinder. For some grinding operations, it may be necessary to wear full face protection in the form of a face shield with safety glasses underneath.

- Turn off the power when the grinder is not in use, to avoid an inadvertent start-up.

- Never clamp a hand-held grinder in a vise. It could shake loose and cause a serious injury.

Pneumatic Tool Safety

Pneumatic tool safety is important because of the risk of serious injury from being struck by an object with extreme force. When using pneumatic tools:

- Always wear eye and hearing protection. Full face protection is also recommended.

- Make sure that air hose connections are secure – check them before using the tool.

- Ensure that the safety clip, or retainer, for attachments is installed and secure. You do not want attachments, such as chisels on a chipping hammer, to be shot unintentionally.

- Use screens to protect nearby workers from being struck by flying fragments when using such tools as chippers, riveting guns, power staplers, or air drills.

- Finally, never point a pneumatic tool toward anyone, including yourself.

Safety with Powder-Actuated Tools

Safety with powder-actuated tools is extremely important. These tools are not guns, but they can cause damage like guns. Remember to read and follow the manufacturer’s operation manual before using powder-actuated tools, and if you haven’t been trained, you shouldn’t use them at all.

Basic safety rules for powder-actuated tools include:

- Do not use them in an explosive or flammable atmosphere.

- Inspect the tool prior to use to make sure it is not damaged and will work properly.

- Never point the tool at anyone.

- Load the tool only when it is going to be used.

- Finally, keep your hands clear of the barrel end of the tool.

Jack Safety

Basic guidelines for jack safety include:

- Set up the jack so that the base rests on a firm, level surface, if at all possible.

- Make sure the jack is centered, to prevent tipping.

- Ensure that the jack head is against a level surface—if the jack head slips, the object being jacked can fall.

- And, be certain that the lift force is applied evenly.

During the actual “jacking” of the object, keep your body out from behind the jacking mechanism.

Safety Switches

Safety switches are a feature of most portable power tools. They allow the tool to be turned off quickly to help prevent, or at least minimize, the chance of serious injury. Here are some common types of safety switches:

- Positive on-off switches are found on small hand-held power tools, such as platen sanders, disc sanders, grinders with less than 2-inch diameter discs, shears, and scroll saws.

- Momentary on-off switches allow the tool to be turned off by a single motion of the same finger or fingers that turn it on. Tools with this type of switch typically include drills; tappers; fastener drivers; horizontal, vertical, and angle grinders; disc and belt sanders; and reciprocating and saber saws.

- A constant pressure switch with automatic shutoff requires constant pressure on the trigger mechanism; when the mechanism is released, the power shuts off automatically. Tools with this type of safety switch include circular saws and chain saws.

What’s Wrong with This Picture?

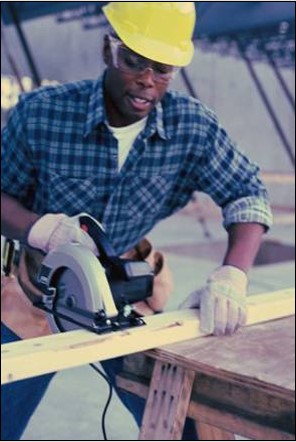

Here’s an exercise to test your general knowledge of portable power tool safety. It is based on an actual workplace accident that was inspected and documented by OSHA. Can you tell what’s wrong with this picture?

An employee is cutting plywood with a circular saw:

- He tapes back the lower blade guard so that it no longer automatically closed over the lower part of the blade when the plywood was not actually being cut.

- He holds the wood with one hand while placing the other end of the wood on the ground; this allows him to operate the circular saw with one hand.

- The saw catches in the wood and kicks back.

- The saw hits the man in the abdomen with the unguarded saw blade, leaving a 10-inch laceration that required a large number of stitches.

What Caused the Accident?

What caused this accident? There are many possible reasons:

- First, the guarding for the saw was disabled. The guard probably got caught in the wood when cutting at a downward angle. The employee had probably cut wood this way before, so maybe he assumed it was safe.

- Second, the piece of plywood was not in a safe position for cutting. To hold the wood in an upright position, he probably exerted a lot of downward pressure, which may have put too much pressure on the blade and caused it to kick back.

- Third, the employee did not have both hands on the saw, so it was impossible to control it when it kicked back.

- Finally, it’s possible that the saw blade was dull, which could have contributed to it catching in the wood.

What Should Have Been Done?

What should have been done in this incident? Think for a moment about the safe actions that the employee could have taken.

- For example, how could this worker have cut the board safely?

– When using a circular saw, the wood should have been laid flat across sawhorses or on a cutting table. In this position, the guard would have moved out of the way as it was designed to—he would not have felt the need to tape it back. He also would have been in a better position to control the saw, with both hands on it, even if the saw had kicked back. – Further, the worker should have inspected the blade first to make sure it was in good condition before using it. Blades should be sharp and have no signs of damage, or they are more likely to produce a kickback.

- What type of PPE should have been worn?

– The type of PPE for any job is determined by the hazard assessment done before the work was started. Flying particles is an obvious hazard, so the worker also should have at least worn protective eyewear to protect his eyes against flying chips.

Questions?

- Do you understand the material on portable power tools?

Now it’s time to ask yourself if you understand the material presented. It is important that you understand how to operate portable power tools safely.

Key Points to Remember

Key points to remember about this training session include the following:

- Keep all portable power tools regularly maintained to make certain they are in good condition.

- Use the right tool for the job. Trying to force a tool to do a job it wasn’t designed for is an invitation to an accident.

- Examine each tool for damage before use. If it appears to be damaged, don’t use it.

- Operate tools according to the manufacturer’s instructions.

- Use the right personal protective equipment to help protect against injury.

This concludes the training session on Portable Power Tool Safety.