Personal protective equipment, or PPE, provides a barrier between you and the hazards of your job. The right PPE, properly used and maintained, can protect you from the hazards involved in the emergency response tasks you perform—and it can help ensure that you are able to go home safe and healthy at the end of your shift.

But for PPE to protect you properly in emergency situations, you have to know how to select the right equipment for the job, understand its capabilities and limitations, use it properly, and remove it safely. We’ll discuss all these important issues and more in this training session.

Table of Contents

Session Objectives

The main objective of this session is to provide you with the information you need to know about emergency response PPE so that you can use this important equipment properly to protect your health and safety. By the time this session is over, you should be able to:

- Select proper PPE for different hazards;

- Evaluate PPE performance and control for PPE-related hazards such as heat stress;

- Know what level of protection is necessary when you enter a spill area;

- Understand how to use and maintain PPE; and

- Follow safe decontamination procedures to prevent exposure to hazardous substances.

What the Law Requires

- All hazardous waste treatment, storage, and disposal facilities, or TSDFs, and all hazardous waste generators are required by law to train employees in emergency response procedures.

- TSDFs and large quantity generators, or LQGs, are required to have a written contingency plan as well as a preparedness and prevention plan that addresses emergency response safety and health issues and preparedness training.

- Small quantity generators, or SQGs, are not required to have a written contingency plan, but they must have a preparedness and prevention plan that incorporates necessary emergency response training.

Are you familiar with our emergency preparedness and response plans? You should be. If there’s anything you need to know about the plans, find out now.

Hazard Assessment

A hazard assessment is essential to understand the types of hazards employees, like you, might be exposed to. It is a requirement of the Occupational Safety and Health Administration, or OSHA, that hazard assessments be performed before PPE is selected. Here is an overview of how a hazard assessment is conducted.

- First, your employer evaluates every job function in every department for potential hazards.

- If any hazards are found during their assessment, they record what the hazards are.

- Then, they determine what part of the body each hazard is a risk to. In this session we’ll focus on the eyes and face, respiratory system, hands, feet, and head.

- Finally, your employer determines what type of PPE will protect against the hazards that are found. For example, if there is an eye hazard present, they will determine if safety glasses are adequate or whether goggles are needed.

Chemical Exposure And Health Effects

The kind of exposure you have to a chemical often determines how the chemical might affect your health.

- The dosage refers to the amount of the chemical you are exposed to. With some materials, it takes a very large amount to do any serious harm, but with others, only a tiny amount can be very dangerous. Dosage also depends on duration of exposure, concentration of material, and exposure pathway.

- Acute effects are short-term effects on the body that usually disappear if you are no longer exposed. Examples include skin irritation from touching a chemical, or irritation of your nose and throat from inhaling fumes.

- Chronic effects are long-term effects that develop over a long period of exposure—even exposure to small amounts. Examples include damage to the liver or other organs, or developing cancer as a result of chemical exposure.

Selecting PPE for Respiratory Hazards

- A key part of your emergency response training involves the PPE that you may need to use in the event of a release of hazardous materials at our facility. We’ll begin our review of PPE by talking about selecting PPE for respiratory hazards. Selection of respiratory protection is based on air monitoring results.

- Powered air-purifying respirators, or PAPRs, may be used in situations that are not extremely hazardous to your health. You should not use a PAPR in atmospheres immediately dangerous to life or health. Such atmospheres are known as IDLH. For example, PAPRs are inadequate in atmospheres where there is insufficient oxygen to keep you alive or in flammable or explosive atmospheres.

- When chemical exposure levels create the possibility of death, serious illness, or injury—or reduced ability to escape—a positive pressure self-contained breathing apparatus, or SCBA, is required.

- In some extremely hazardous atmospheres, airline respirators equipped with an escape air supply might also be used.

Think about the respiratory protection you may need in an emergency.

Selecting PPE For Skin Hazards

Many chemicals and biological agents can cause health problems when they come in contact with unprotected skin. Health effects can range from problems, such as dermatitis and burns, to more serious problems, such as when hazardous substances are absorbed into the bloodstream through the skin, which can lead to tissue and organ damage.

- In emergency situations involving less hazardous substances, chemical-resistant clothing, such as coveralls, gloves, and boots, might be sufficient to protect against harmful skin exposure.

- When more dangerous substances are involved and skin exposure could result in a substantial possibility of immediate death, serious illness, or injury, or reduced ability to escape, a fully encapsulating suit would be required.

Protecting your skin during emergency response operations is essential. Do you know what type of PPE you need to wear?

Selecting PPE For Eye Hazards

You could encounter variety of possible eye hazards in emergency response operations as well, for example, smoke, poisonous gas, thermal hazards and fire, and falling or shifting debris from fires or explosions. Resulting eye injuries could be severe.

- On the basis of the potential hazards and injuries, the National Institute for Occupational Safety and Health, also known as NIOSH, says that the best eye protection is a full-face respirator, which might also be required to protect against respiratory hazards.

- When a full-face respirator is not required, the next best eye protection is goggles under a face-shield.

- And when the hazards are more moderate, hybrid safety glasses with foam or rubber around the lenses may be sufficient to protect your eyes. They generally provide better protection than conventional safety glasses with side shields.

- Wraparound safety glasses that convert to goggles with a soft plastic or rubber face seal may also be used in some circumstances, and may offer better peripheral vision than conventional safety goggles.

Think about the type of eye protection you need to use to do your job in an emergency response operation.

Selecting PPE for Head Hazards

As with other types of PPE, if head hazards are found in your workplace, your employer selects head protection specific to each hazard. Here are some examples:

- Hard hats protect the head from impact or penetration. They are usually made of high-density polyethylene so that they are lightweight, but strong enough to protect against falling objects.

- Electrical insulation hard hats are used to reduce the risk of electrical shock and can protect against such hazards as power lines. However, do not assume that a hard hat will protect against electrical hazards just because it is not made of metal.

- Bump caps should be used around low-hanging objects such as pipes, steel structures, or machinery parts. However, bump caps are not intended to protect against falling objects or electrical hazards.

- Hard hats in the workplace must meet ANSI standards and be marked with “Z89” to show that they meet these standards.

Selecting PPE for Foot Hazards

Wearing foot protection is another important way to reduce the risk of serious injuries.

- Steel-toed work boots or shoes protect against rolling or falling objects that could crush your toes.

- Some footwear provides metatarsal protection—that is, it protects the bones of the foot behind the toes. Other types of protective footwear provide steel in the heel and along the ankle to help keep the ankle from being twisted.

- The sole of the shoe or boot can protect against different kinds of hazards. Some soles are puncture-resistant to protect against sharp objects, while slip-resistant soles prevent injury on wet or slippery floors, and still others prevent absorption. Be aware that surfaces with water on them require a different kind of slip-resistant sole than surfaces with oily substances.

- Chemical-resistant boots are needed if there is a risk of splashing from liquid chemicals, acids, or caustics.

- Waterproof and cold-weather footwear may be needed if you work in wet, muddy, or cold conditions. Rain boots made of PVC or rubber can help keep feet dry. Special liners can help insulate feet against extreme cold.

- Lastly, protective footwear must be marked “Z41” to show that it complies with ANSI standards.

Evaluating PPE Performance

In addition to identifying hazards, the performance characteristics of PPE must be taken into account when selecting protective equipment. Most chemicals will eventually get through even the best PPE and protective clothing, given sufficient concentration and enough time. The time it takes for a chemical to get through PPE is known as “breakthrough time.” Breakthrough time depends on three things.

- The first is the nature of the chemical. Strong corrosives, for example, will eat through PPE faster than many other substances.

- The second consideration is temperature. Temperatures of both the substance and the surrounding environment must be taken into account. Higher than normal temperatures result in faster breakthrough time.

- The third issue is the thickness of the PPE material. Use of thicker materials generally increases breakthrough time.

In addition to breakthrough time, you have to think about other PPE limitations, such as the absorption capacity of PAPR canisters. Be careful not to exceed this capacity.

Are you familiar with the breakthrough time for the PPE you use?

Task-Specific Conditions and Durations

When you are performing emergency response operations in hazardous situations, you need to be mindful of the risks and limitations of your PPE. You must not remain in contaminated areas long enough to:

- Risk hazardous levels of exposure that could affect your health or compromise your ability to perform assigned emergency tasks safely.

- Exceed the limitations of PPE and protective clothing. For example, you must always take into account limitations such as breakthrough time and absorption capacity of PAPR canisters.

Protection Levels

Now let’s look at the four basic protection levels of PPE.

- Level A protection is required when the risk of exposure is greatest. Level A requirements would apply in areas with toxic vapors or gases, or for initial surveillance of an unknown but possible highly hazardous area. This level requires the highest level of respiratory, skin, and eye protection. Examples of Level A protection include a fully encapsulating chemical- and vapor-resistant protective suit and a positive-pressure SCBA.

- Level B protection is required when the highest level of respiratory protection is necessary, but a lesser level of skin protection is needed. Examples of Level B protection include positive-pressure full-face SCBA or positive pressure-supplied air respirator with escape SCBA. In addition, inner and outer chemical-resistant gloves would be required along with hooded chemical-resistant clothing or coveralls and chemical-resistant boots. This level of protection is always necessary for any site thought to be contaminated.

- Level C protection is required when the concentration and type of airborne substances are known and it is safe to use an air-purifying respirator instead of an air-supplied respirator. Examples of Level C protective equipment include a full-face PAPR, inner and outer chemical-resistant gloves, hard hat, escape mask, and disposable chemical-resistant outer boots.

- Level D is the minimum protection required. Level D protection is sufficient when there are no contaminants present or when the work operation will not create the potential for splashes, immersion, or inhalation of hazardous levels of chemicals. Examples of Level D PPE include gloves, coveralls, safety goggles, face shields, and chemical-resistant steel-toe boots or safety shoes.

Think about the different levels of protection you might need to use to respond safely to an emergency involving released hazardous materials.

Protection Levels: Matching Quiz

Let’s quickly review protection levels with a matching quiz. Match the protection level on the left with the phrase on the right. Let’s go over the matches together.

- Level A protection is required when exposure risk is greatest.

- Level B protection is required when the highest level of respiratory protection is necessary but a lesser level of skin protection is needed.

- Level C protection is required when the type and concentration of contaminants is known and it is safe to use an air-purifying respirator.

- Level D protection is required when no contaminants are present or when work operations will not create the potential for splashes, immersion, or inhalation of hazardous levels of chemicals.

How did you do? Did you get all the matches right?

PPE Selection

Now it’s time to ask yourself if you understand the information presented so far. Do you understand what we’ve said about:

- Assessing emergency response hazards and selecting appropriate PPE to protect against hazards?

- Evaluating the performance of PPE to make sure it provides adequate protection?

- Protection levels and the type of PPE required for each level— A to D?

It’s very important to understand all this information so that you can always be equipped with the right PPE to protect against the hazards you might face in emergency operations.

Let’s continue to the next slide and talk about controlling PPE hazards.

Controlling PPE Hazards

In addition to protecting yourself against environmental hazards by using proper PPE, you also need to protect yourself against potential hazards created by the use of PPE itself. These potential hazards include:

- Heat stress due to wearing a lot of hot, confining PPE—especially in hot environments—which can interfere with the body’s normal temperature management system;

- Cold stress due to inability to wear sufficient clothing under PPE to protect against cold temperatures; and

- Individual health conditions, which might place some workers at greater risk of heat stress or other problems when using some of the types of PPE required for emergency response.

Heat Stress

Heat stress is a serious concern because it has a negative impact on your performance and safety while you are engaged in emergency response operations. The risk of heat stress when wearing emergency response PPE depends on several factors, including:

- Type of PPE worn—the more equipment and the more encapsulating the equipment, the greater the risk;

- Level of physical exertion required to perform the work;

- Temperature and humidity in the environment;

- Physical fitness and heat acclimatization; and

- Amount of water you drink while working.

Controlling Heat Hazards

To control heat hazards caused by required emergency response PPE, you should:

- Drink a sufficient amount of water to replace fluids lost by sweating;

- Use the buddy system, whenever possible;

- Double check your work for errors that you might make because of heat-related fatigue;

- Limit the amount of time you work in hot, confining PPE; and

- Alternate work time with rest periods that allow you to cool off and recover. Think about the ways you can protect against heat stress when using PPE in emergency response.

Cold Stress

In some emergency response situations cold, not heat, may be the problem.

- Extreme cold can affect your health, job performance, and safety.

- Wind, snow, and rain can intensify the effects of the cold, and

- The cold can lower body temperature to dangerous levels, resulting in hypothermia. If you are exposed to extreme cold for long periods, frostbite is also possible.

Controlling Cold Hazards

To control cold hazards while performing emergency response work:

- Wear as much cold-resistant clothing as possible under PPE and other protective clothing;

- Limit work time in very cold conditions;

- Take rest periods in a warm, dry place;

- Use the buddy system and watch one another for signs of hypothermia and frostbite; and

- It’s also important to stay hydrated in cold weather as well as hot weather. We tend to drink less when we are not hot, yet the body can get dehydrated just as fast.

If you are ever involved in emergency operations in extremely cold conditions, do you know what you need to do to protect against cold stress?

Proper Use of PPE

Even the best emergency response PPE will not protect you adequately if you fail to use it properly.

- Always select the right PPE for the hazards and task you are performing. Think about both the capabilities and limitations of the PPE and the specific hazards it is designed to protect against. The PPE you choose should provide maximum protection for the specific situation in which it will be used.

- Inspect PPE before each use and look for cracks, tears, holes, or other damage that could render the equipment ineffective in protecting against hazards. Worn or damaged PPE should not be used, but rather exchanged for new equipment.

- Don and remove PPE safely. Make sure all snaps, straps, zippers, and so on are properly fastened to prevent exposure to hazardous substances in the work environment. PPE must be removed carefully as well to prevent contact with contaminated outer surfaces.

- Make sure you get a good fit, too. You’ll get an advanced custom fitting for respirators, shoes, and encapsulating suits. Other PPE, such as gloves, goggles, and so on, come in a variety of sizes or may be adjustable, so you’ll most likely fit those yourself. Make sure PPE fits comfortably and allows you to move around easily.

Proper Use of PPE (cont.)

- Practice using emergency response PPE. Make sure you know how to use it properly before you go into a hazardous environment. Wearing protective equipment such as encapsulating suits can be cumbersome and require extra energy and oxygen consumption. To get used to your PPE, you should practice working with it, watching for signs of fatigue, dehydration, heat stress, anxiety, or other negative reactions.

- Follow work/rest schedules. To avoid heat stress, cold stress, and overexertion, be sure to alternate work and rest periods during which you can remove PPE, rehydrate, and take a break to allow your body to recover. Even short breaks from hot, confining equipment can help sustain performance and prevent illness.

- Use the buddy system, whenever possible. This ensures that you have a coworker at hand to check you for signs of stress, dehydration, or exposure to hazardous substances. If you are overcome, someone will be there to help get you to safety.

Think about procedures for donning, fitting, and removing PPE.

PPE Maintenance

In order to function properly, PPE must also be properly maintained.

- Place disposable PPE in proper containers.

- Clean other PPE with soap and water and allow it to dry thoroughly.

- PPE should be stored:

– In a clean, dry place,

– Where it won’t be damaged,

– Away from heat sources and sunlight, and

– Away from temperature extremes.

- Respirators should be stored carefully so that the facepiece won’t become distorted. Place the facepiece so that the rubber and plastic parts maintain their natural shape. Make sure other objects are not stored on top of the facepiece or pressing up against it.

Do you always follow proper procedures for maintenance and storage of emergency response PPE? Remember, if PPE isn’t cared for properly, it may not protect you adequately against hazards.

PPE Use

Now before we continue, let’s take a moment to make sure you understand all the information presented in the previous slides. Do you understand what we’ve discussed about:

- Controlling PPE-related hazards such as heat or cold stress?

- Proper use of emergency response PPE?

- PPE maintenance and storage?

This is essential information that will help you use your emergency response PPE safely.

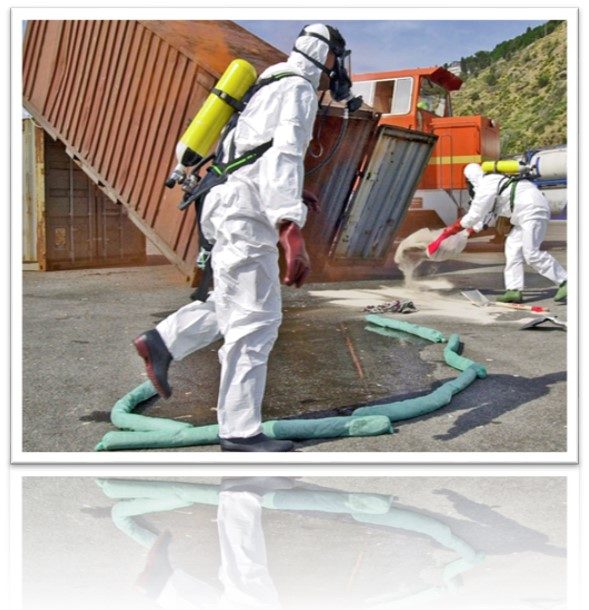

Decontamination Procedures

Before leaving an emergency response site, you must go through a decontamination procedure to safely remove PPE.

- Decontamination begins at the deluge shower, in most cases. If you are wearing impermeable protective clothing, step under a deluge shower and flush clothing and PPE with water.

- Proceed to the boot wash and scrub boots with a decontaminant or soap and water to remove chemicals and mud.

- Then remove all clothing and place it in marked containers. Generally, you should remove the most heavily contaminated items first—for example, boots, suit, gloves, and then undergarments.

- Your respirator is the last item to be removed. Before removing it, take a deep breath and hold it. Then remove the mask, step under the shower, and flush the top portion of your body before you resume breathing.

- Take a thorough shower, washing carefully with soap and water all over your body.

- Finally, proceed to the dressing room where you can change into clean work clothing or your street clothes if it’s the end of your shift.

Think about the decontamination procedures you must follow.

PPE Use: True or False?

Let’s test your knowledge of what we’ve discussed about PPE use now with a short true/false quiz.

- You should inspect PPE once a week. True or false?

– The correct answer is false. You should inspect it before each use.

- If there is a risk of heat or cold stress while performing emergency response duties, you should work with a buddy, if possible. True or false?

– The correct answer is true. You and your buddy can keep an eye on one each other and keep each other safe.

- PPE should be dried in the sun or near a heat source after cleaning. True or false?

– The correct answer is false. Keep PPE away from sunlight and heat sources. These could damage the equipment.

- Short breaks from work when using encapsulating suits do little good. True or false?

– The correct answer is false. Always follow established work/rest schedules. Even short breaks help sustain performance and prevent illness and injury when using hot, confining PPE.

How did you do? Did you get all the answers right?

Key Points to Remember

Here are the main points to remember from this training session on PPE for emergency response:

- Be aware of hazards related to the particular emergency response tasks you perform.

- Understand the different levels of protection required for different levels of hazards.

- Know which PPE to use, when to use it, how to use it, and how to maintain it.

- Inspect PPE before each use.

- Understand the importance of following proper decontamination procedures.

This concludes the training session on PPE for emergency response.